In this business-centric blog, we will emphasize an extremely important subject, galvanizing plants. A wide range of issues will be covered ranging from basic definitions to benefits of the industrial process.

Before we take a deep dive into the industrial subject, let’s make an effort to understand the industrial term which is our defining socio-economic life.

Learning about galvanization

What is galvanization? For many of you, it is a new term. Galvanization is a scientific process wherein a thin layer of zinc metal is applied to iron/steel-made objects to prevent them from corrosion.

Hot-dip galvanizing plant

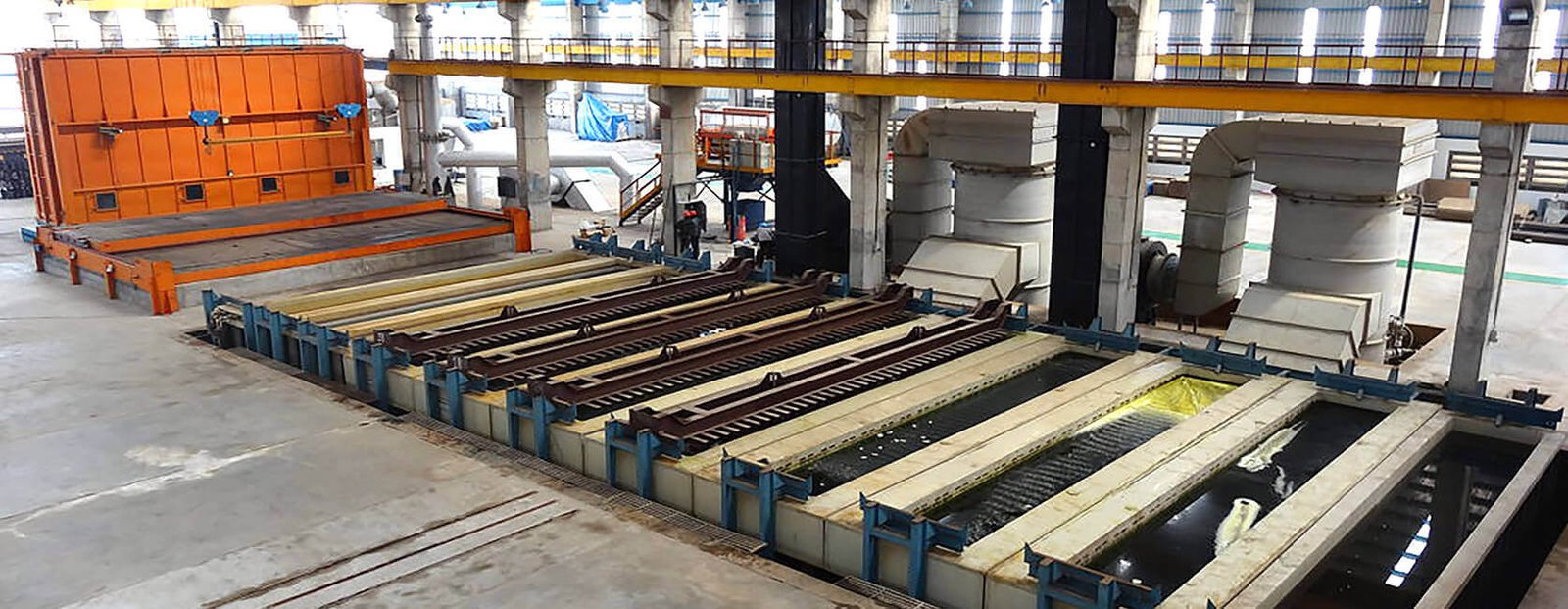

According to experts, the most common method for galvanization is hot-dip galvanizing. Under this popular process, steel sections are dipped in a bath of molten zinc. The zinc layer acts as a shield and protects the metal from corrosion and in turn, increases its durability many times. Hot-dip galvanizing plants in Ahmedabad are tailor-made for the purpose. Galvanizing plant manufacturers are using the latest machines and tools to manufacture an excellent plant.

The three steps of the hot dip galvanizing plant

The hot dip galvanizing process comprises three major steps:

- Surface preparation

- Galvanizing

- Inspection

How does the zinc layer protect iron structures?

There is a scientific reason. As zinc metal is hyperreactive, it reacts with air to form a hard layer of zinc oxide on the metallic structure. This layer works as a protective shield and prevents air from passing through it. Subsequently, protecting the iron/ steel from corrosion.

From basics, let’s now shift our focus to important reasons why industries galvanize steel?

Durable: Galvanization has been transforming many industries with its incredible feature. It multiplies the durability of the product many times.

A worthwhile investment: Initially it appears expensive, in the long run, it is a worthwhile investment. A galvanized structure lasts around 100 years.

The coating thickness depends upon the gauge of the metallic structure. The thickness of galvanization can be measured easily, whenever you wish. It is a non-destructive method…

Scientific process: Zinc oxide that acts as a protective layer occurs through a proven scientific process. It’s a natural metallurgical reaction.

Galvanizing is visible: Right from the beginning, galvanized steel structure starts showing its significance. Therefore, galvanizing is visible. It starts working from day one.

Complete coverage: Hot dip galvanizing helps in creating a very strong bond between zinc and steel. Thus it provides complete coverage, amazing strength, and durability. Owing to these features, the iron-made structures remain protected even during harsh weather conditions.

Summary

Hot dip galvanized steel is engulfing all of us in many different forms. It is all around us. Numerous companies, industries, sectors, etc. are leveraging the phenomenon, including automobiles, railways, power transmission, windmills, infrastructure, etc. Over the years, it has become integral to our lifestyle, and rightly so.

Buy the galvanization plant from Arvind Corrotech

Arvind Corrotech is an industry leader offering full-spectrum galvanization solutions. Our quality-driven product range includes Turnkey Hot Dip Galvanizing Plants, Pulse Fired High-Velocity Furnace, Process Tanks, Chemical Storage Tanks, and pollution control equipment.

If you are on the lookout for anything related to pollution control equipment, then end your search with Arvind Corrotech. Let’s connect for a mutually beneficial collaboration.