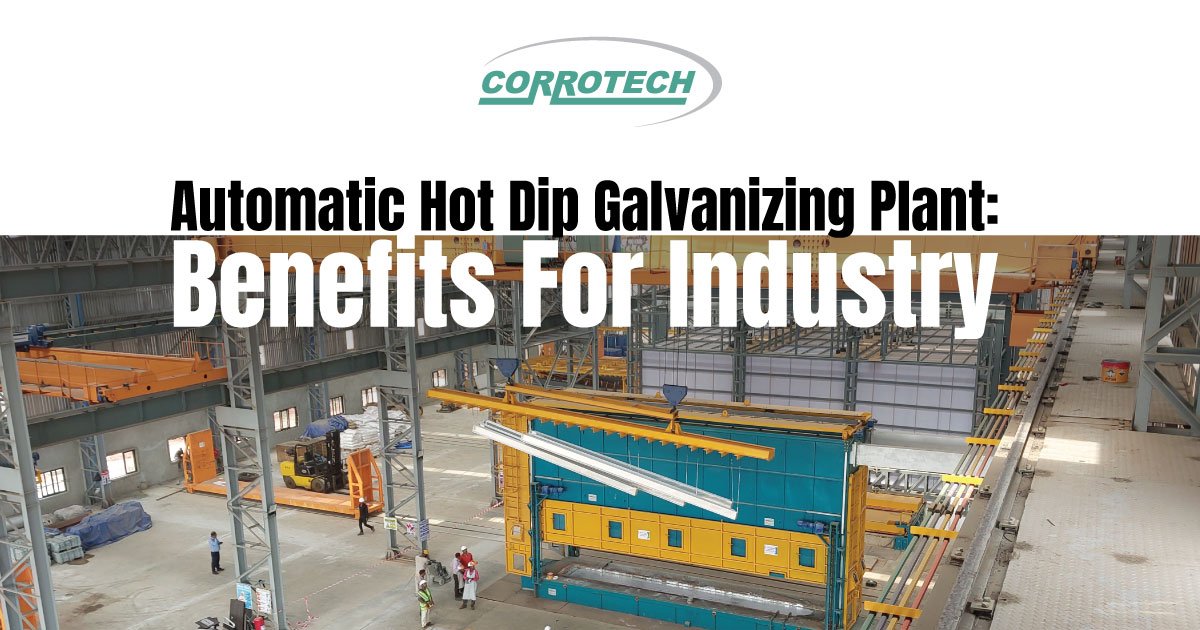

With the advent of innovative technology, galvanization has witnessed sweeping changes. Automatic hot dip galvanization plant is a classic example of harnessing of innovative technology to drive considerable benefits.

For the unawares, a hot dip galvanization plant is a scientifically designed plant comprising a variety of machines, tanks, and tools to convert typical steel-made items into galvanized steel. Iron or steel-made items are immersed in a molten lava of zinc. A metallurgical reaction takes place between iron and molten zinc, resulting in a zinc coating over the metal.

Benefits of Automatic Hot Dip Galvanizing Plant

Why automatic plants are important? Over the years, demand for automatic plants has witnessed a substantial surge, riding on industries’ inclination towards automatic plants.

Some of the important benefits comprise:

- Cost reduction

- Increased productivity

- Enhanced reliability

- Optimized performance

Cost reduction

Every business faces pressure to reduce production costs. The automation of hot dip galvanizing plants is a step forward. Automation is a strategic step towards cost containment.

Increased productivity

Automatic hot dip galvanization plant executes the commands precisely and timely and in exact sequences. Thereby, eliminating manmade errors. As a result, the production process becomes more linear and cost-effective.

Enhanced Reliability

Since the automatic hot dip galvanizing plant is technology-driven and has low human intervention, it demonstrates enhanced reliability during the production cycle. Reliability is one of the major benefits that sparkles with automation.

Optimized Performance

Every company that uses a galvanization plant would like to see that their plant performs flawlessly without major downtime and aids in production. A typical galvanization plant has its challenges. With an automatic hot dip galvanizing plant, companies can get optimized performance.

Given the technology and benefits that automatic hot dip galvanizing plant brings onboard, a wide range of industries are installing them in their facility.