Eliminating dust, debris, fumes, and a host of other pollutants released during a wide range of processes in manufacturing setup can be a daunting task.

When workers work in a tight indoor manufacturing facility, they are exposed to a variety of harmful particles, leading to health issues. Therefore, the fume extraction system assumes significance. The scientifically designed machine is crucial to keep the surrounding environment free from pollutants for anyone working there.

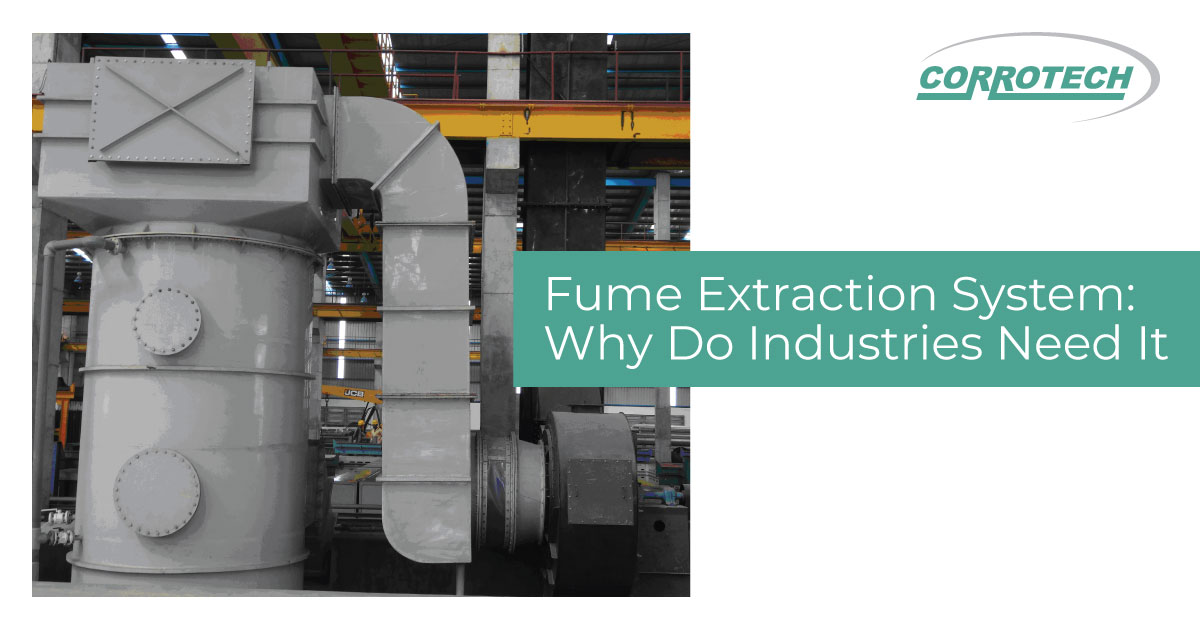

Understanding the Fume Extraction System

It is essentially a scientific machine that has powerful fans to extract dust, toxic fumes, and a host of other harmful particles. Into a contained filtration system. In addition to protecting your workforce from health hazards, the machine also acts as a shield for machines and equipment. The clean air is released back into the environment.

The strength of the extractor fans and fume extraction filters decide the quality of the fume extraction system. Don’t forget to raise the query regarding these two vital components of the environment-friendly system.

Where to use the System?

Who can install this system? What sort of industries use this environment-friendly system? It is suitable for manufacturing companies where pollutants and dust particles are released into the air during a variety of processes, for example, textile, chemical, plastic, tyre, paper, etc.

In addition, many industrial processes, like soldering, welding, sanding, grinding, spraying, etc. emanate hazardous particles into the air. Here, the use of a fume extraction system is gaining prominence.

Choose the Best Fume Extraction System

If you care for your workforce, then certainly, you shouldn’t think twice about installing a fume extraction system. The market is flooded with manufacturers and suppliers providing the product. Choose the product after due diligence. Why settle for less, when you have the option to get the best!