Category: Blogs

History has witnessed plenty of chemical disasters, leading to the loss of life and assets. Many of these disasters are preventable, provided industrial chemicals are stored properly and as per the instructions needed to store chemicals. Considering the importance of the safe storage of chemicals, chemical tank fabrication is gaining prominence.

From the safety of the workforce to the impact on the ecosystem, those employed in factories wherein chemicals are used, need to learn the importance of ideal chemical storage.

Importance of storing chemicals correctly

Product life

When you are storing chemicals properly, means, you are preserving them properly for future applications. That’s why perfect chemical tank fabrication is important.

For a moment, think about milk at home, if you don’t store it properly, it will become sour and can result in health-related issues.

Safety

This is one of the most important benefits of storing chemicals properly. Industrial chemicals require ideal storage tanks and trained staff to handle them as they are a threat to the safety of both workers and the ecosystem around them. Safe storage ensures the safety of workers as well as the environment.

Save environment

Improper storage of chemicals can lead to a spill of chemicals all around. When industrial chemical enters the environment, it badly impacts the flora and fauna. It’s difficult to save the ecosystem from contamination. For detailed information in this regard, you can connect with a leading chemical tank fabrication company in Ahmedabad.

Whatever vegetable, fruit, or cereals, we consume, it is cultivated in soil. Contaminated soil impacts the nutritional value of the produce.

With the advancement in technology and research, chemical storage methodology has improved considerably. Environment-friendly products are available in the market. By using the perfect chemical storage tank, your manufacturing company can play its role in saving the environment around us!

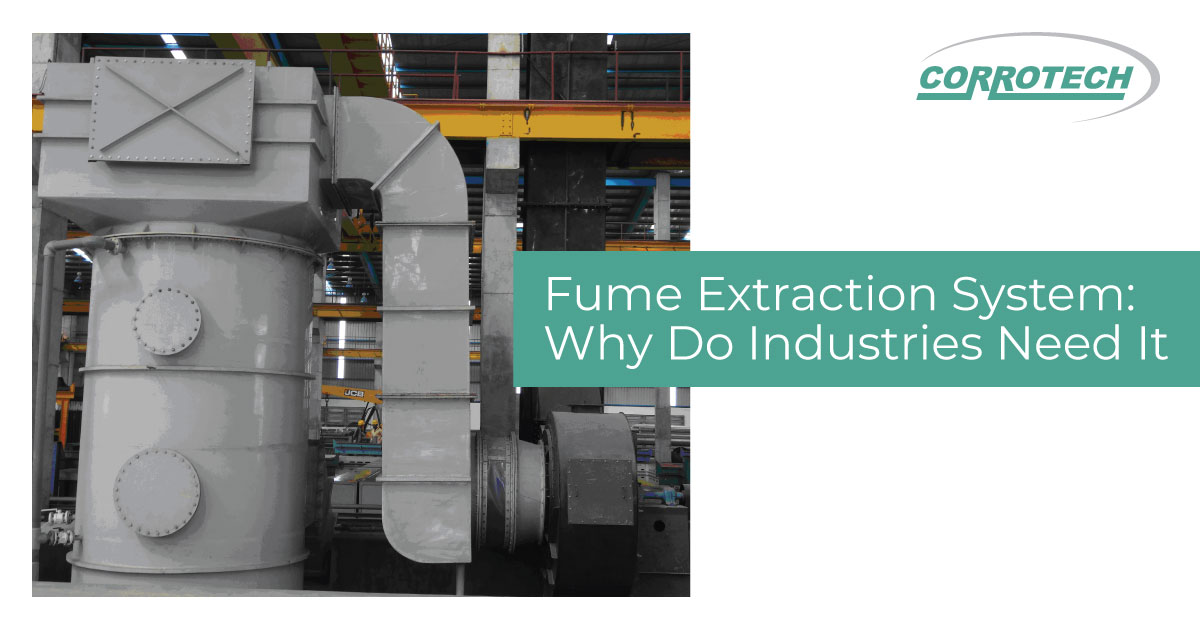

Eliminating dust, debris, fumes, and a host of other pollutants released during a wide range of processes in manufacturing setup can be a daunting task.

When workers work in a tight indoor manufacturing facility, they are exposed to a variety of harmful particles, leading to health issues. Therefore, the fume extraction system assumes significance. The scientifically designed machine is crucial to keep the surrounding environment free from pollutants for anyone working there.

Understanding the Fume Extraction System

It is essentially a scientific machine that has powerful fans to extract dust, toxic fumes, and a host of other harmful particles. Into a contained filtration system. In addition to protecting your workforce from health hazards, the machine also acts as a shield for machines and equipment. The clean air is released back into the environment.

The strength of the extractor fans and fume extraction filters decide the quality of the fume extraction system. Don’t forget to raise the query regarding these two vital components of the environment-friendly system.

Where to use the System?

Who can install this system? What sort of industries use this environment-friendly system? It is suitable for manufacturing companies where pollutants and dust particles are released into the air during a variety of processes, for example, textile, chemical, plastic, tyre, paper, etc.

In addition, many industrial processes, like soldering, welding, sanding, grinding, spraying, etc. emanate hazardous particles into the air. Here, the use of a fume extraction system is gaining prominence.

Choose the Best Fume Extraction System

If you care for your workforce, then certainly, you shouldn’t think twice about installing a fume extraction system. The market is flooded with manufacturers and suppliers providing the product. Choose the product after due diligence. Why settle for less, when you have the option to get the best!

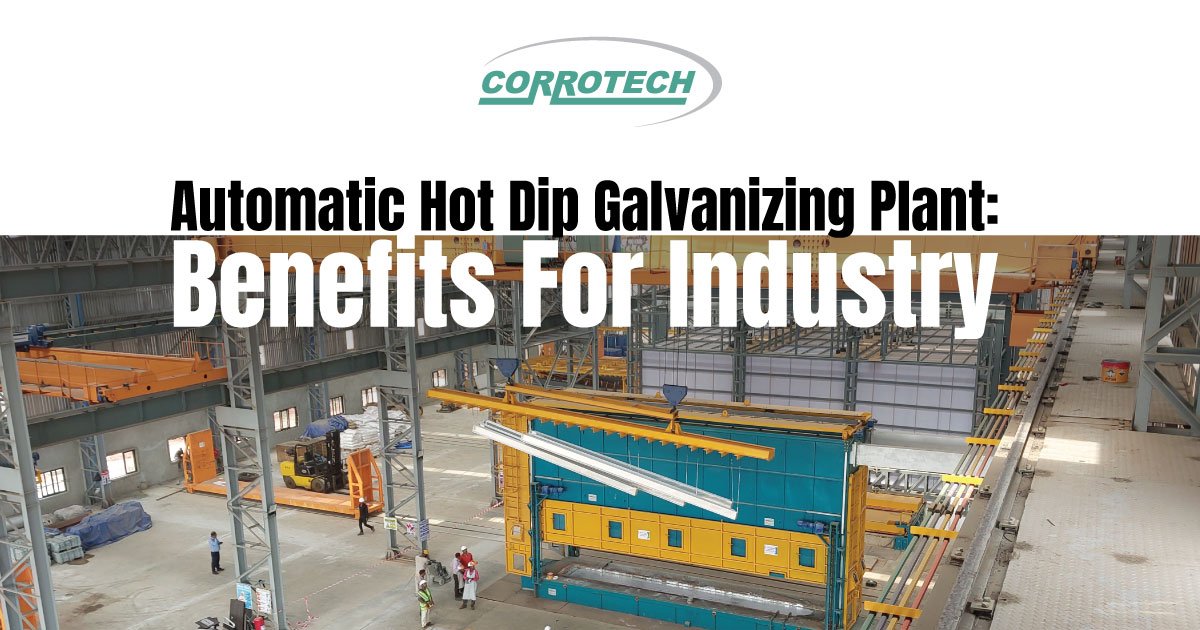

With the advent of innovative technology, galvanization has witnessed sweeping changes. Automatic hot dip galvanization plant is a classic example of harnessing of innovative technology to drive considerable benefits.

For the unawares, a hot dip galvanization plant is a scientifically designed plant comprising a variety of machines, tanks, and tools to convert typical steel-made items into galvanized steel. Iron or steel-made items are immersed in a molten lava of zinc. A metallurgical reaction takes place between iron and molten zinc, resulting in a zinc coating over the metal.

Benefits of Automatic Hot Dip Galvanizing Plant

Why automatic plants are important? Over the years, demand for automatic plants has witnessed a substantial surge, riding on industries’ inclination towards automatic plants.

Some of the important benefits comprise:

- Cost reduction

- Increased productivity

- Enhanced reliability

- Optimized performance

Cost reduction

Every business faces pressure to reduce production costs. The automation of hot dip galvanizing plants is a step forward. Automation is a strategic step towards cost containment.

Increased productivity

Automatic hot dip galvanization plant executes the commands precisely and timely and in exact sequences. Thereby, eliminating manmade errors. As a result, the production process becomes more linear and cost-effective.

Enhanced Reliability

Since the automatic hot dip galvanizing plant is technology-driven and has low human intervention, it demonstrates enhanced reliability during the production cycle. Reliability is one of the major benefits that sparkles with automation.

Optimized Performance

Every company that uses a galvanization plant would like to see that their plant performs flawlessly without major downtime and aids in production. A typical galvanization plant has its challenges. With an automatic hot dip galvanizing plant, companies can get optimized performance.

Given the technology and benefits that automatic hot dip galvanizing plant brings onboard, a wide range of industries are installing them in their facility.

A variety of industries require large-sized industrial tanks to store, process, and transport industrial chemicals. Over the years, custom polypropylene tanks have assumed significance in various industries, given their unique features, properties, and applications.

Understanding polypropylene

It is a thermoplastic which is light in weight. Considering its various features and properties, it has an edge over polyethylene, making it one of the most sought-after materials in the industry for manufacturing tanks.

Unique features of custom polypropylene tank

A polypropylene tank is identified with a variety of unique properties, making it perfect for industries. Some of the major unique features are:

- Low moisture absorption

- Tolerates high and low temperature

- Resistant to inclement weather conditions

- Excellent thermal insulating properties

- Brilliant dielectric properties

- High tensile strength

- Excellent compressive strength

- Brilliant thermal insulating properties

Before placing your order to a tank manufacturer, don’t forget to consider the above features. Manufactured keeping in view industry standards, these types of tanks are suitable for storing various types of industrial chemicals and processing of chemicals.

Are custom polypropylene tanks suitable for transportation?

Yes, industries can transport chemicals from one place to another using the tanks.

Industries using PP Storage Tank

The brilliant product has found usage in different types of industries. These include Pharmaceuticals, Chemicals, Petroleum, Steel, Textile, Plastic and many more. While choosing the product, don’t forget to discuss your storage needs, like industry, capacity, chemicals to be stored, etc.

Types of design of custom PP storage tanks

These tanks are available in various shapes and sizes. According to your industrial requirement, you can choose the shape. Some of the common shapes comprise vertical tanks, horizontal, below, or above ground.

A few leading companies PP storage tanks manufacturers hold expertise to deliver custom polypropylene tanks. This expertise is acquired after years of experience and also requires modern technology and machines.

From pharmaceutical chemicals and refined fuel to fertilizers and raw materials used for manufacturing plenty of things, like sodium hydroxide and aluminium sulphate, industrial chemical storage tanks are used for a variety of applications.

Chemical storage tank supplier manufacture different types of industrial tanks. Choose the tank according to your industrial needs. Entering into deep dialogue to choose the apt tank serves the purpose.

How do chemical storage tanks help industries? What are the benefits of chemical storage tanks for industries?

Major benefits of chemical storage tanks supplied by chemical storage tank supplier

Here are the benefits of quality-driven chemical storage tanks for industries:

Improve onsite safety

Safety of the workforce and assets at sites ensures efficient production. Chemical spills and leaks are a serious threat to your industry. Choosing a meticulously designed chemical storage tank ensures health and safety requirements.

Manage environment protocols and threat

Spills and leaks pose a great threat to the environment. Local rules and regulations, if not followed could lead to massive penalties. Quality-driven chemical storage tanks help industries to successfully meet environmental threats and local rules. For in-depth information, connect with a leading chemical storage tank supplier in Ahmedabad.

If your industry isn’t following local environmental laws, sooner or later, you will be under their radar and be ready to face their wrath.

Maintain the integrity of the product

In the absence of a robust storage tank, sites pose a threat of contaminating both raw materials and finished products. Most chemicals are corrosive in nature. What does it mean? Unless a tank is resistant to corrosion, product contamination may take place. Therefore, it’s important to choose a tank that is designed to store chemicals.

Leading chemical storage tank supplier is equipped with technology and machines to roll out customized tanks. Why settle for quality when you have the option to choose the best?

With the advent of technology and continued innovation in the field of galvanization, the galvanization technology and process are witnessing drastic changes. Considering the benefits and importance of automation for galvanization, demand for automatic galvanizing plant is rising substantially. Rightly so!

Benefits of Automatic Galvanization Plant

Traditional galvanization processes require plenty of machinery, and manpower, leading to a high cost of galvanization. High costing directly impacts end users.

Here are some of the major benefits:

1. Automation makes the process leaner and more rational:

This means; production time or turnaround time doesn’t face an unnecessary shutdown. As a result, manpower lost during the shutdown can be substantially reduced.

2. Dependence on manpower is reduced substantially:

A blend of technology and innovation has significantly reduced the dependence of plants on manpower. In contrast, a traditional plant’s performance depends on the performance of the workforce. Now it’s all technology driven. In fact, manpower is empowered to manage and control various functions intelligently and smartly.

3. User-friendly interface:

Modern technology has empowered the manufacturer of automatic galvanizing plant to customize critical functions to suit the requirement of the industry. It wasn’t possible in the traditional plants.

4. Easy to calculate ROI:

You don’t require a management degree to calculate ROI. Automated design and control panels allow you to fetch critical data and arrive at a logical conclusion. Plenty of bottlenecks have been addressed with the support of technology.

Choosing the Plant Manufacturer

Indian market is flooded with automatic galvanizing plant manufacturers. Carry out due diligence exercises while choosing the manufacturer and supplier. Brand reputation assumes significance here. Thoroughly examine the credibility of the company with whom you are all set to join hands.

Massive investment is required to procure the plant. That’s why we recommend you ensure the credibility of the company. Visiting the factory premises makes sense, allowing you to ensure the competency of the manufacturer!

Many of you may not be aware of the process of galvanization, yet we all come across a wide range of galvanized products, including power transmission towers, telecom towers, high-rise electricity poles, metallic flyovers, solar panels, sports goods, etc.

Over the years, galvanization has witnessed sweeping changes, driven by continued innovation in galvanization engineering and zinc galvanizing plant. The zinc kettle is an integral part of the galvanization process. How does a zinc kettle help in galvanization?

Before taking a deep dive into the subject, it makes sense to learn about the vital engineering vessel.

Understanding Zinc Galvanizing Plant

It is a specially designed structure fabricated from premium quality steel material having low carbon and silicon contents. The structure is engineered to immerse steel or iron-made items into the molten zinc, leading to the formation of a thin zinc coating. Since the kettle is used for galvanization, it is known as a zinc galvanizing plant.

Zinc kettle manufacturers are engineering a wide range of zinc kettles. Depending on your industrial requirement, you can choose the shape and size of the kettle.

Shelf life of a zinc kettle:

The zinc kettle is exposed to treacherous and challenging conditions. Shelf life varies from company to company. Generally, it has a shelf life of 10 years.

Benefits of galvanization:

The zinc coating developed as a result of galvanization in zinc kettles brings along with it plenty of benefits. These include:

- Lower cost than stainless

- Requires less maintenance

- The lowest long-term cost

- Increased durability

- Long life expectancy

- Reliable and trustworthy

- Coating life and performance are reliable

- Outstanding resistance to mechanical damage

- Protection of even small areas of steel exposed to harsh weather

- Far better than the traditional method of painting

Due to the paucity of space, we can’t share many other key details about the product. For more details, you can connect with a leading zinc kettle manufacturer.

Over the years, industrial HDPE Chemical Storage Tanks have assumed significance considering their benefits for a variety of industries. Industrial chemical storage tanks are specially designed to store industrial chemicals, acids, solvents, etc. Choosing a suitable tank is always a challenge for industry owners and decision-makers.

You would be surprised to learn that many companies realize after buying the product that the tank they have just bought doesn’t meet their industrial requirements.

How to choose the best quality tank for your industry? This blog will serve as a guide in this regard. Whether you’ve been buying the HDPE tank or any other industrial tank for years, or shopping the tank as a beginner, this guide is definitely for you.

A brief guide to choosing the premium quality HDPE chemical storage tank

Consider the chemical to be stored

To begin with, the first step you can take to choose the best HDPE tank is to consider the chemical to be stored. At the same time, carefully consider the properties of the chemicals to be stored inside the tank.

Types of chemical storage tank material

When you are sure about the chemical to be stored and its unique physical and chemical properties, you can then move towards the best tank material suitable to meet your industrial requirements.

Industrial tanks are made up of a variety of materials, including HDPE, PVC, Steel, FRP, PVDF, Plastic, etc. Before choosing the material, have a long discussion with a few leading industrial tank manufacturers in Ahmedabad, India.

Size

This is again an important step to be considered when choosing the tank. Here size means the capacity of the tank. What type of chemicals do you want to store for your industry? Consider the capacity of the tank.

If you are planning to buy an HDPE tank to store industrial chemicals for your company, discuss the capacity with the premium quality HDPE chemical storage tank manufacturers and suppliers.

Durability

The next step, you can consider when choosing an industrial tank, like an HDPE tank is – the durability of the tank. Every material has definite durability. How much that industrial tank will last matters for your business. Short life means you have to invest in storage tanks every now and then.

When you buy long-lasting industrial tanks, you are ensuring the quality as well as durability of the tank. Higher durability also means you don’t have to invest time and again in storage tanks.

Why quality matters

Harsh chemicals gradually wick into the walls of the chemical storage tanks over time. The chemical spreads into the structural area of the tank. The structure begins to break down and eventually the tank collapses.

If quality isn’t up to the mark, it will impact the overall life of the storage tank. Therefore, it makes sense to buy the premium-quality chemical storage tanks

Conclusion

This guide on choosing the premium quality HDPE chemical storage tank will definitely benefit you, helping you to get the best product for your manufacturing unit. Important aspects like tank design, shape, size, capacity, etc. should never be undermined when choosing an HDPE tank.

Don’t underestimate this term, pickling room by thinking about that delicious pickle made by your grandmother. It is a scientific

In a hot dip galvanization process, the pickling room has assumed huge significance given its benefits in galvanization. How does it benefit the process of galvanization? What are the benefits of Encapsulated pickling room for the galvanization industry? These and many similar questions will be addressed in this blog.

Before we take a deep dive into the important subject, it makes sense to learn about the vital subject in simple language, so that readers can connect with the blog.

Understanding pickling room

In a scientifically designed galvanizing process, steel is pickled in a specific acid after the degreasing process and before pre-fluxing. How does it matter? The pickling process removes the iron oxides or scales present in the steel surface, making it ideal for the next stage of galvanization.

Challenges associated with the open pre-treatment systems

According to experts, with open pre-treatment systems, it is inevitable that there is a considerable quantity of aggressive chemicals in the air around the pickling baths than in other areas. you would be shocked to learn that it applies even if the baths are only minimally heated or not heated at all. As a result, man and material, both are exposed to harmful acid fumes. Given these challenges, innovative abatement systems were invented.

From the basics, let’s now move toward the core subject of this blog.

Learning about encapsulated pickling room

An abatement system is designed to enclose the pretreatment area or the acid tank in a separate room. The room has the efficiency to separate the process area where acid fumes are generated from the surrounding operational areas. How does the design of the special room benefit the process of galvanization? The special design ensures safety and prevents damage by keeping operators (workers), overhead cranes, machines, and the structure of the tanks. The galvanizing environment remains healthy and safe.

Benefits of abetment systems for acid fumes

It’s now time to shift focus to the benefits of abatement systems. Here are some of the important benefits of encapsulated pickling room

- Increased productivity

- Reduced maintenance cost

- High shed life

- Prevents corrosion of structure due to acid fumes

- Chances of air pollution mitigated

- Safety risks eliminated

- Workers health ensured

For detailed information, you can get in touch with a leading pickling room manufacturer and supplier in Ahmedabad, Gujarat.

Importance of design of encapsulated pickling room and abatement system for acid fumes

Design and structure of encapsulated pickling room

An innovative design of the structure plays a significant role in the efficiency of the pickling room. Here are a few benefits of a quality-driven structure:

- standalone enclosure mounted on a robust steel structure is a standalone enclosure

- The enclosure room is made using polypropylene sheets

- Motorized door for incoming material

- Cranes run outside the encapsulated area

- The structure is equipped with roof lights, viewing windows, emergency exits, etc.

- Roof sealing arrangements

Here, it’s important to mention that design and features vary from manufacturer to manufacturer.

Conclusion

Encapsulated pickling room is a terrific product for the galvanization process. Choose a quality product for your galvanization plant!