Category: Blogs

This blog is informative, particularly for those who work in industrial units that use acid storage tanks and chemical storage tanks for various purposes. In this blog, we are going to highlight acid storage tanks, their benefits, and their advantages for different types of industries.

Learning about industrial acid tanks

Large and bulky-sized tanks that are designed and manufactured to store and process different types of chemicals for industrial applications are called industrial storage tanks.

Let’s now shift our focus to the unique features of industrial chemical storage tanks. How will you identify the quality of the industrial tanks? In the ensuing sections, you will learn about the salient features of quality-driven storage tanks.

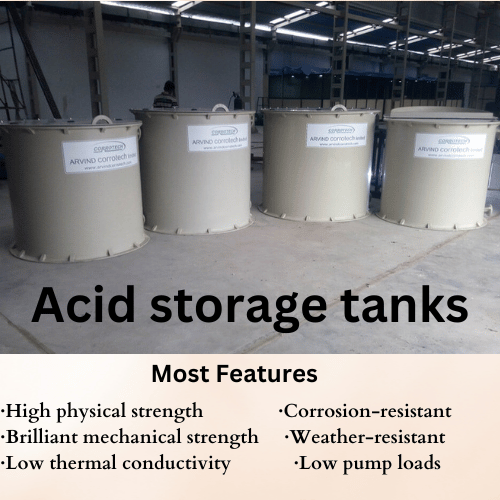

Salient features of quality-driven acid storage tanks

Here are the salient features of quality-driven industrial tanks:

- It is adaptable to a wide range of temperature

- High physical strength

- Brilliant mechanical strength

- Low thermal conductivity

- Excellent insulating material

- Corrosion-resistant

- Weather-resistant

- Low pump loads

- Easy to handle

- No maintenance

- Durable & having a long service life

- Economical & cost-effective

Before considering these features, you should buy industrial tanks for your manufacturing unit.

Material of acid Storage tank

Others manufacture industrial tanks using premium-quality polypropylene sheets, HDPE, and FRP. Every material has its unique features and benefits.

Which material is suitable?

You can connect with a leading chemical storage tank manufacturer to learn more about the storage tanks. The material of the tank varies from chemical to chemical.

Benefits and advantages of acid storage tanks

Industrial requirements necessitate the design of bulk–sized tanks for bulk storage of chemicals and acids; these tanks are cost–effective in the long run, as bulk buying chemicals is cheaper compared to retail, while also reducing the number and cost of deliveries. Furthermore, chemical storage is used in a variety of operations when necessary, making industrial acid storage tanks ideal for storing, processing, and safely transporting chemicals.

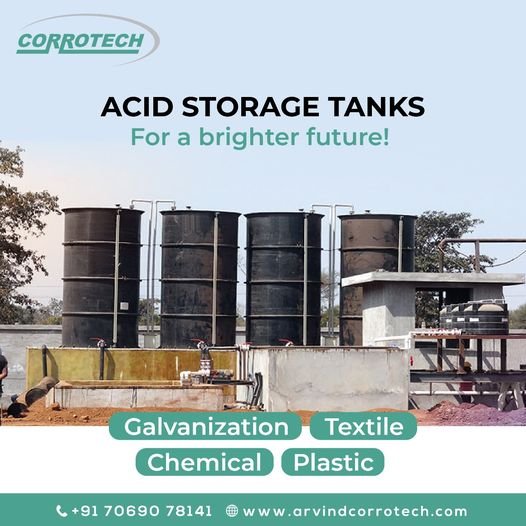

Industries using acid storage tanks

Numerous industries are drawing benefits from chemical storage tanks, PP storage tanks, HDPE storage tanks, etc. These include Pharmaceuticals, Chemicals, Petroleum, Steel, Textile, Plastic, and a host of others. For more information, you can connect with a leading chemical storage tank manufacturer in Ahmedabad, India.

Process tank

The engineer designs industrial tanks to blend, separate, cool, and purify a wide range of processes and sub-processes. While placing your order, you can discuss the need and requirements of your industry with the chemical storage tank manufacturer.

Conclusion

Acid storage tanks are integral to a wide range of manufacturing industries. Quality makes the difference in this era of tough competition. Many industrial tank manufacturers have flooded the market. Only buy the product from an established chemical storage tank manufacturer.

Galvanization is everywhere. It’s all around us. In fact, it wouldn’t be an exaggeration to the fact that we are surrounded by a plethora of things made of galvanized iron and steel. Since we are talking about galvanization, it makes sense to bring into focus the significance of the galvanization plant. How the scientifically designed unit is changing the socio-economic scenario around us? In this blog, we are highlighting turnkey hot dip galvanizing plants and their impact on changing the fortune of the automobile spare parts industry.

History of galvanized steel and automobile industry

According to industry experts, it wasn’t until the late 1980s, that the Japanese began focusing on automobiles that uses galvanized steel in their design. It makes sense to share that galvanized steel was indispensable in Japan, considering its geographical location. It is a country with a substantial coastal environment that creates heavier levels of oxidation and corrosion. Therefore, galvanization was necessitated.

Let’s now shift our focus to the core subject of this blog, how hot dip galvanization is changing the fortune of the automobile industry.

Galvanized steel parts are protective in nature

It is a proven fact that the galvanized steel part that is being used in cars, bikes, trucks, etc. lends protective cover to the vehicle. Sharp corners and edges are prone to oxidation. Galvanized parts used here protect the vehicle from corrosion.

Galvanized steel can be used immediately

Steel plates, frames, rooftops, etc. galvanized by using the hot dip galvanizing plant can be used immediately, unlike painted material. On the contrary, painting requires preparation of the surface, an inspection of the surface, painting/ coating, etc. It’s a time-consuming process. If you are an auto spare parts manufacturer, you can connect with a leading galvanizing plant manufacturer in Ahmedabad.

Increased durability

This is again an important factor of galvanized steel that drives the automobile industry to move towards galvanized steel. Increased durability means reliability. At the same time, it decreases the maintenance cost or saves your hard-earned money in maintaining your favorite car. You don’t have to drag your car for repairs and maintenance. That’s why even buyers, the end user prefers car manufactured using galvanized steel parts.

Self-healing property of galvanized steel

Oxidized parts corrode rapidly leading to the collapse of the vehicle. Whereas galvanized steel has this unique feature of self-healing. What does that mean? It means the galvanized steel provides automatic protection for damaged areas. The zinc coating will corrode especially the steel. As a result, sacrificial protection is provided to the damaged areas.

Over the years, the use of zinc-coated spare parts and bodies in auto manufacturing has gained momentum. At the same time, the anti-corrosion feature is also a brilliant marketing tool for the automobile industry. Galvanization empowers automakers to attract customers by offering anti-rust warranties.

Conclusion

Considering the benefits of galvanizing plants for the automobile industry, many automobile spare parts manufacturers are moving towards galvanized steel. And rightly so.

Can you imagine life without water? Apart from drinking and irrigation, the widely used natural asset is also essential in a variety of industries, including textile, chemical, pharmaceuticals, steel, etc. Water is utilized to accomplish various industrial operations in an industrial setup. As a result, it becomes polluted with numerous pollutants. This water is discharged in an open environment leading to pollution. Subsequently, it brings focus on the ETP treatment plant by ETP plant manufacturer.

For the unaware, the ETP treatment plant is also known as a water treatment plant across industry circles. In this blog, we are going to highlight the benefits of buying the plant from ETP plant manufacturers in Ahmedabad.

Learning about the sophisticated plant

The high-end plant is designed and manufactured to treat polluted and contaminated industrial water, making it reusable and safe for discharge.

How does the environment-friendly plant help in the anti-pollution drive?

Prevents waterborne pollution

By using the high-end machine, waterborne pollution is prevented. Otherwise, it leads to sludge and becomes a cause for spreading waterborne diseases. Here are a few examples of waterborne diseases cholera, diarrhea, typhoid, amoebiasis, hepatitis, gastroenteritis, giardiasis, campylobacteriosis, scabies, and worm infections.

Safeguard public health & safety

Oil and gas wastewater has been found to contain high organic, salt, and radioactive material concentrations. This wastewater if discharged without treatment spread on roads, and farmlands, leading to biological toxicity. That causes a variety of diseases. In this regard, you can connect with a few established ETP plant manufacturers.

Improved efficiency of a manufacturing plant

Having water treatment plants in your manufacturing preemies makes the operation substantially efficient and reduces operating costs. Therefore, it makes sense to install a water treatment plant at the unit. Such scientifically designed systems remove the smallest to the largest pollutants, including inorganic pollutants and garbage.

Keeps industrial equipment safe and running

How does the ETP treatment plant save machinery? Since wastewater contains damaging pollutants as a result of the manufacturing process, if the water is not treated properly, it can damage machinery and tools. Safe equipment means increased longevity and durability. Therefore, it’s an investment worth making. For detailed information, you can connect with a few recognized ETP plant manufacturers.

Minimize waste

This is again an important benefit of installing water treatment plants at your manufacturing premises. As a responsible manufacturing industry, you aspire to reduce the flow of wastewater from your unit. What better way than using the scientific plant? At the same time, the plant helps in saving money and ensures that polluted wastewater is treated and discharged in a safe way, saving the environment. In case, you have any doubts, you can connect with a few leading ETP plant manufacturers.

Without a doubt, you would agree that industrial wastewater treatment is highly beneficial for a variety of manufacturing companies. Aside from helping in creating a safe and healthy environment, the plant boosts the productivity of manufacturing units.

Conclusion

Given the benefits of the plants, companies cutting across expertise and geographic locations are showing interest in ETP treatment plants. Never settle for quality, only choose quality-driven ETP plant manufacturers to buy the product.

Acid storage tank manufacturers are manufacturing a wide range of acid storage tanks for storing various types of industrial acids. The market is flooded with tanks made of a different material. Every material has its own benefits and disadvantages. Business owners face issues galore in choosing the ideal acid tank for their industry. In this blog, we are going to focus on similar pivotal issues.

Before we take a deep dive into the subject, it makes sense to learn about the unique features of a quality-driven.

Salient features of quality-driven acid storage tanks

Every business searches for quality acid storage tanks since quality tanks by established acid storage tank manufacturers have a wide range of benefits and manufacturers. What are those benefits? For the benefit of readers, we are sharing those features:

- Corrosion resistant

- A protective cover prevents bumps

- The matching lock cover protects

- Recyclable

- Safe to use

- Resin rich surface

- Reliable

- Integral leg supports

- Durable

Consider these features, when you place your order with a famous industrial tank manufacturer in Ahmedabad. Don’t forget to evaluate the acid tank, you are all set to buy on the above parameters.

Let’s now shift our gear to the core subject.

What material should I choose for acid storage tanks?

Acid storage tank manufacturers are using different types of materials for manufacturing acid storage tanks. Here are a few famous materials used to manufacture industrial acid tanks.

Polyethylene tanks

This material is generally less expensive. And has found usage in various industries. Whether it is linear (LLDPE or HDPE) or cross-linked (XLHDPE), polyethylene-made acid storage tanks are resistant to chemicals and abrasion. However, this material isn’t as strong as FRP. At the same time, it has a lower maximum temperature threshold, making it ideal for storing a few acids. Entering into a dialogue with a tank supplier will definitely help.

FRP (Fiber Reinforced Plastic) Tanks

According to industry experts, FRP (fiber-reinforced plastic) tanks are suitable for larger vessels, taller and narrower vessels, and elevated temperature applications. In this regard, you can connect with a few prominent acid storage tank manufacturers. FRP-made acid tanks by a leading tank supplier with certain durakane resins can handle up to 250°F for short periods without impacting the quality of the tank or vessel. Here, we would like to mention that FRP-made vessels aren’t ideal to store sulfuric acid. In this regard, you can connect with a few Tanks manufacturer for further info.

Steel and high alloy tanks

Metallic industrial storage tanks, like steel and high alloy tanks are designed for applications that require pressure ratings above atmospheric pressure. Having a discussion with the tank supplier will help you in learning about the product.

Industrial storage tanks on the basis of design

Some of the commonly used industrial storage tanks in industries are fixed-roof tanks, horizontal tanks, external floating roof tanks, internal floating roof tanks, pressure tanks, doomed external floating roof tanks, LNG tanks, and variable vapor space tanks.

Conclusion

Before finalizing the tank, share your requirement with acid storage tanks manufacturers. Only choose the tank that meets your requirement. Why settle for inferior quality, when you have the option to choose the best!

Over the years, pickling has assumed significance in surface treatment plant and pickle processing plant given its numerous benefits for galvanization and engineering-based industries. With the advent of innovative technology, pickling plant manufacturer is getting empowered to roll out a wide range of pickling tanks.

As indicated by the introduction and title, we are going to highlight the importance of pickling plant in surface treatment. Before we take a deep dive into the industrial subject, let’s understand the pickling process in simple language.

Learning about pickling

What is pickling? Do you know, what is the metal treatment process? People often imagine mango or chilly pickle, when they are asked about pickling. Here we are talking about metal treatment plant, it is also famous as pickling processing plant or surface treatment plant in industry circles.

In metal engineering, pickling refers to the metal treatment process. Under this process, superficial impurities are removed from the surface of the metal. Then why it is called pickling? Since the process comprises using an acid solution which is called pickle liquor, it has become famous as a pickling process. And the plant which is designed for the pickling process is known as the pickle processing plant.

Coming to the composition of the pickle liquor, it mostly depends on the type of metal on which it’s all set to be used. Let’s understand this with a few examples, for low carbon steel, pickle liquor comprises hydrochloric or sulfuric acid, whereas, for high-carbon steel, pickle liquor comprises acids like phosphoric or nitric acid. For further information, you can connect with a leading pickling plant manufacturer in Ahmedabad.

Benefits of pickling

From the basics, let’s now shift toward another key element of this blog, the benefits of pickling or surface treatment plants. It has been observed that newly manufactured metal plates, rods, pipes, etc. develop a layer of impurities on the surface when exposed to air or weather conditions. An oxide layer comes up on the surface. This layer reduces various traits and properties of the metal, making it unsuitable for various industries, like galvanization and precision-based engineering.

According to industry experts, there are plenty of ways to remove oxide and various other impurities from the steel surface. However, pickling has become one of the most reliable methods of removing impurities and oxide layers, since the process is simple to plan and implement. During the pickle processing plant, metal-made items like iron rods, plates, and pipes, are immersed inside the tank with acidic pickle liquor. The pickle liquor eats away the oxide layer and other superficial impurities, without disturbing the underlying steel. In this regard, you can connect with a leading pickling plant manufacturer.

Does an iron pole require with no oxide layer require pickling before galvanization?

Many people think on this line. But the fact is just because an iron piece has an oxide layer, it doesn’t mean, it’s completely pure. The item still contains many other impurities. That’s why pickling is important.

Conclusion

We are confident, this blog will expand your knowledge about pickling. Pickling plant manufacturer is manufacturing a wide range of pickle processing plant. Before choosing the plant, enter into a dialogue with the manufacturer to share your requirement.

Galvanizing has emerged as one of the most reliable techniques to apply a coating on iron-made items. A robust zinc kettle is an essential element of this entire process. A scientifically designed zinc galvanizing plant comprising a wide range of processes for zinc coating on a wide range of products, like pipes, wires, rods, and components enables successful galvanization.

The magic of the zinc layer

The extremely thin zinc layer adds plenty of features to the coated metal, including resistance to corrosion and durability. You don’t require deep knowledge to solve this question. The durability of metal is directly proportional to its ability to resist corrosion. Since the zinc layer imparts incredible properties to the metal, it lasts up to 70-80 years. Even more than that. Zinc kettle manufacturer hold professional experience in building zinc galvanization plant ‘s machines and tools. You can raise your doubts and queries to the manufacturer.

An important question arises here, why is zinc used in zinc galvanizing plant and not any other metal? This will remain the key focus of our blog. Many people, especially students, want to learn about this mystery. In this blog, we are going to solve this vital question.

Why not copper in place of zinc?

That’s an obvious question many of you might be thinking to raise. Why not copper in place of zinc for carrying out the galvanization process and applying a coat, after all even copper doesn’t rust either. According to the experts, zinc protects steel-made items from rusting in many ways, copper can’t.

Metals that are more reactive in nature, protect metals that are comparatively less reactive by losing electrons first. According to metallurgy experts, zinc is more reactive than any kind of steel, making it ideal for the galvanization process. On the contrary, steel is more reactive than copper. Your answer lies here. Since steel is more reactive than copper, if we apply the copper coating for galvanization, if copper got scratched, the steel beneath it would corrode faster whereas copper maintains its original shape. Therefore, it makes sense to use galvanization. Consequently, giving rise to the demand for zinc kettle, zinc galvanizing plant, and zinc kettle manufacturer. Does it mean copper can’t be used to galvanize steel?

Copper is required for weathering steel

What is corten steel or corten weathering steel? Copper has found usage in processing weathering steel. It is famous in industry circles as COR-TEN steel. It is a high-strength steel alloy. Steel-made items when galvanized with copper become weathered in appearance. It is necessitated to meet the architectural requirement. So, next time when someone says can we use copper for galvanization? You have the right answer.

Some metal oxidizes faster than others

Yes. That’s absolutely correct. Under the process of galvanization, zinc oxidizes and endures acid corrosion sacrificially to steel. It means zinc is straightaway in contact with acids and oxygen that target steel. Zinc coating saves the steel beneath from corrosion. A zinc kettle as the name indicates is ideal for hot–dip galvanization.

Summary

Zinc-based galvanization is changing the face of the galvanization industry across the globe, including India. With the rapid rise in economic activities across the globe, zinc kettle manufacturer is continually getting orders.

This is going to be an informative blog with a clear focus on ETP treatment plant. Before we move forward and take a deep dive into the subject, it makes sense to learn about ETP effluent plant in simple language.

What is an ETP plant?

To make it simple for you, it is a scientifically designed plant with requisite machines and tools designed to treat industrial wastewater. The main objective behind this plant is to prevent environmental degradation and pollution that occur due to the discharge of industrial wastewater.

Let’s now shift our focus to the core issue, how to choose the best ETP plant for your manufacturing company.

Determine the components required to treat

Every manufacturing unit generates waste and harmful particles and components during the manufacturing process. The first step a company can take when planning to buy the plant is – to determine the components to be treated. You can assign this responsibility to an experienced production unit supervisor or technician.

Quality and amount of waste waster

The next step you can take is – to determine the quality and amount of the wastewater to be treated by using the ETP process. This will help you determine the capacity of the plant you are planning to buy for your manufacturing plant, like a textile unit, plastic factory, chemical process unit, paint manufacturing company, etc.

Based on biological treatment

This is again a major factor in determining the ETP treatment plant. A few plants are designed exclusively for the treatment of biological waste. In such plants, microorganisms that are suited to decompose the waste component present in the factory waste are mixed in the chamber. If your factory discharges biological waste, then no point in buying the plant suitable for chemical treatment.

Based on chemical and inorganic components

This type of ETP effluent treatment plant is designed to treat chemical and inorganic components that emerge from a manufacturing unit, like a chemical and paint factory. If you are managing a textile unit, wherein a wide range of chemicals are used during production, then you must consider this type of plant. Don’t forget to raise your requirements with a leading manufacturer.

Cost factor

This is one of the most important factors you should consider when buying the ETP treatment plant for your factory. The cost of the plant depends on a wide range of factors, including the material used for manufacturing the plant, the quantity of wastewater to be treated, the required output of the plant, the quality of treated water, the average life span of the plant, etc. Also, the size of the plant largely depends on the capacity of the plant, you have chosen.

Cost Comparison

There are numerous companies manufacturing ETP process plants in Ahmedabad, India. When planning to buy the plant, evaluate a few leading manufacturers on major parameters, like cost, energy efficiency, output, the material used, and life span. These factors allow you to choose the best plant for your factory.

Conclusion

We hope this blog will help you in choosing the ideal ETP treatment plant for your factory. In this era of rapid industrialization, it is our responsibility to save the environment. Buying an ETP effluent treatment plant is the right decision in this direction.

Over the years, the galvanizing industry has grown manifold, riding on ever-increasing demand for galvanized products across the globe, including in our very own India. Galvanizing plant setup is highly sophisticated engineering, only a few turnkey hot dip galvanizing plant manufacturer and supplier hold expertise in the domain. Effective consulting with a prominent manufacturer will go a long way in this regard. This brief guide will help you meet your industrial requirement.

Why should you consider galvanizing plants?

In this section, we are going to highlight a few important factors that favour a galvanizing plant setup, if you are considering entry into the galvanization business. These include:

- Short production times

- Streamlined process

- Reduced cost

- Affordable costing

- Reduced labour costing

- Cost savings

- Growing demand for galvanized products

- The durability of galvanized products

Apart from these features, we recommend you to meet a leading company in this area. Their engineers will help you learn the essentials related to the important plant.

Purchasing an existing plant

Experts into galvanizing businesses suggest taking over an existing galvanizing plant as it’s more advantageous to purchase an existing business in comparison to starting from scratch.

Existing revenue cycle

When you build a plant from scratch, you have to struggle to bring in revenue right from the word go. On the contrary, an existing plant has a steady income as it has a client base in its funnel.

Operational efficiency

This is again a huge advantage of galvanizing plant set by leading galvanizing plant manufacturers. As an owner of a business, you don’t have to worry about the operational efficiency of the plant, since the plant is already pilot tested by the manufacturer.

Are you planning to enter into a galvanizing business?

Entering into a dialogue with a few entrepreneurs who are managing a galvanizing plant setup will considerably help you to understand the galvanizing business and how it is going to help your business.

Here we would like to recommend you connect with entrepreneurs from other cities. Why so? It’s unlikely that the local competitors would be eager to speak with you. Obviously, why would they like to guide and educate a future competitor? Whereas galvanizing plant setup owners from far away cities will have no objection as they are fully aware that since you are from a different city, you are not going to steal their local customers. Sounds interesting! It’s a bitter truth.

The bitter truth is it can take a while to find an entrepreneur from the crowded market who will be excited to discuss with you the business of galvanization, market demand, the future of turnkey hot dip galvanization plants, etc.

Important features of a galvanizing plant setup

Before you buy or acquire a galvanizing set up in Ahmedabad, India, examine the plant on major quality parameters.

- Excellent design

- Quality of the machinery

- Cost-effectiveness

- Robust setup

- Impeccable commissioning

- Technology used

- Power efficiency

- Durability

It’s important to carry out due diligence exercise, then regret it later.

A few leading engineering companies in galvanization also hold professional expertise to deliver and supply acid storage tanks. Such manufacturers are known as acid storage tank manufacturers.

How many times, have you imagined about the quality of steel around us? How the flyover bridge still remains intact though more than 50 years have passed? That power pole you saw during childhood is still brightening? How does it happen? Don’t be shocked, when we say, the automatic hot dip galvanized plant ’s impact is all around us and it plays a significant role in our day-to-day lives.

For the unaware, the hot dip galvanizing process is a scientifically designed process for galvanizing steel or iron. As part of the process, metal-made items are immersed in the molten lava of zinc, leading to the formation of a zinc coating. This coating imparts numerous qualities to the coated material, including corrosion resistance.

Let’s now shift our focus to the core issue of this blog, 5 major reasons why industries must galvanize steel before using it.

Galvanizing means durability

Over the years, it has been proved that galvanizing is durable. That’s the reason, it has been largely used by plant and storage tanks manufacturer across the globe, including India. According to industry experts, galvanized steel-made items and structures can last up to 100 years.

Galvanizing is environment friendly

You would agree that the long-term durability that comes along with galvanized steel reduces the burden on the environment. Subsequently, it supports sustainable development. In this era of rapid industrialization, environment-friendly structure and product are getting prominence. And rightly so. The automatic hot dip galvanizing plant industry is witnessing tremendous growth, riding on its significance and advantages for a wide range of industries.

Galvanizing is cost-effective

It’s a myth and perceived notion that hot dip galvanizing is expensive. People think galvanizing is expensive as it brings along with it numerous properties. The paint looks good, initially, it’s cheap. However, you will have to paint the metallic items time and again to save it from corrosion. Also, painting cost increases depending on market dynamics. However, galvanizing costs have remained stable. Initially galvanizing may sound expensive, however, in the long run, it pays off. You don’t have to paint the metallic item, time and again. Subsequently, it is being relied on by plant and storage tanks manufacturer.

Galvanizing is reliable

Yes, that’s absolutely right. Galvanizing is definitely reliable in comparison to a host of other methods to control corrosion. The zinc coating formed as a result of the automatic hot dip galvanizing plant has been found to be consistent, reliable, and durable.

Galvanizing provides incredible coverage to surface

The hot dip galvanizing creates a robust and reliable bond between zinc and steel, leading to the formation of a coating that will last for generations. Also, along with the robust surface, it also provides superior coverage. Hence, the galvanized structure remains protected for years.

Conclusion

We are hoping, this blog will erase many of your myths regarding galvanization and its viability. Next time when you see an electric pole still transmitting power though very old, don’t get surprised. It has happened because of an automatic hot dip galvanizing plant.

Industries cutting across domain expertise are drawing benefits from the incredibly scientific process, including, plant and storage tanks manufacturer.