There are several hot dip galvanizing plant manufacturer Ahmedabad India, provide the galvanizing plant. With the numerous years of experience in the field, Arvind Corrotech is the leading turnkey hot dip galvanizing plant supplier.

The galvanizing plant is with the aid of using par one of the maximum ecological strategies of galvanizing the metal with the zinc. The process is done to make the meta corrosion-free and make it durable for a long time. The manufacturerus all in one package with the several units and provide the hot dip galvanizing. With the packages in which metal are uncovered to severe atmospheric conditions. The hot dip galvanizing firms make these products to galvanized with the zinc.

- Metal Pipes

- Electrical Poles

- Road Side Barriers

- Steel Towers Used For Electrical Transmission

- Cable Trays

- Steel Towers Used For Mobile Towers

- Fasteners

- Hardware Industrial Items

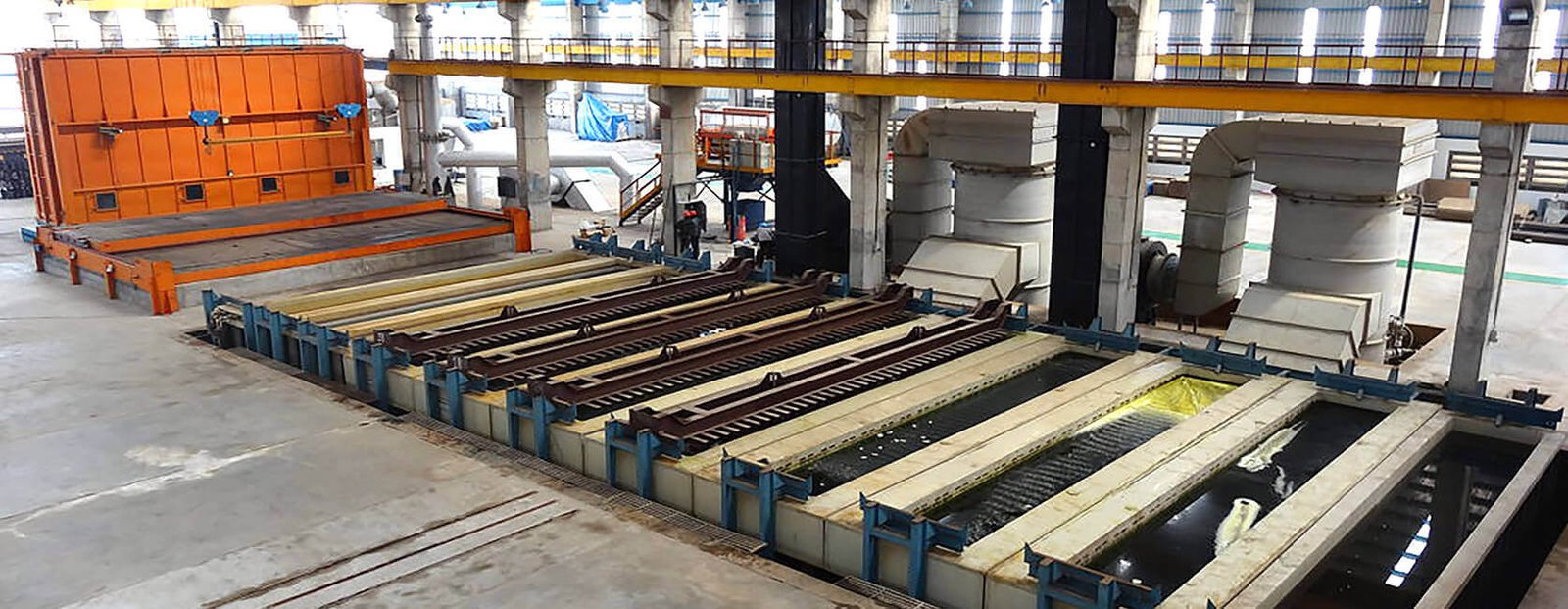

This plant is a genuine production system throughout some steps of the galvanizing plant. Other pre and post processes should be followed by the plant exporter. A spectrum of the pickling or process tanks used for removing the extra dust, and they consist of the acid or other chemicals.

The tanks are resistant to a wide range of chemicals, also they have great mechanical properties. The tanks are supplied from the exporter Ahmedabad India available in the PPH pp and pp-FRP as well. All the storage tanks should be easy to operate, and the tanks should be manufactured in vinyl ester fitted with the granite.

All the tanks are available in various shapes and sizes that suit every batch of the pickling material. The things such as sheet metal components, wire, pipe mills, and cr mills can be pre-processed before galvanizing plant.

Components To Be Used For Galvanizing Plant:

- Pre-Treatment Tanks

- Pulse Fired High-Velocity Furnace

- Zinc Kettle

- Acid Fume Extraction System

- Flux Heating System

- Acid Storage Tanks

- Effluent Treatment Plant

The zinc galvanizing process can be followed step by step by using the component listed above.

The Hot Dip Galvanizing firms make the galvanizing plants that can help you in galvanizing with the:

- Rapid Application

- Reliability

- Proper Mechanical Resistance

- Lower Production cost

- Easy Maintenance & Testing Of Galvanizing Quality

- Ultimate Protection

At Last,

The material can be galvanized by using the perfect hot dip galvanizing plant if it is employing top quality that credits all the components of the plant. Besides, to check the associated with the galvanizing plant, you should consider the top manufacturer, supplier, or exporter.